The Evolution of Forging

- Debbie Arnott

- Jan 23, 2025

- 1 min read

Updated: Mar 9, 2025

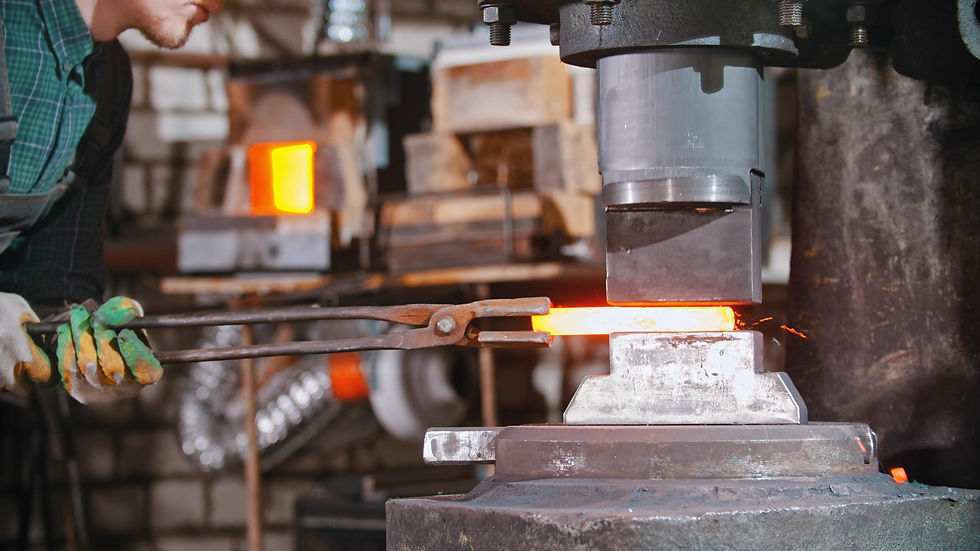

My introduction to forging began during my apprenticeship at Thackray’s, where the company produced oversized forgings and carried out several machining operations to finish the Charnley Hip Stem. At the time, producing a forged stem that even roughly resembled the final product was considered cutting-edge technology.

Since then, I have had the opportunity to collaborate with numerous forging facilities, contributing to the development and testing of orthopaedic implants. For many years, forge design was often regarded as “black magic,” where engineers relied on traditional practices—using the same flash gap regardless of part size and compensating for tool cavity underfill by simply adding more material. It was not uncommon for engineers to be surprised when oversized parts or lap defects occurred.

Today, with the advancement of forging simulation software, forge design has transitioned from an art to a science-based discipline. This technology enables precise simulation of material flow within the die cavity, accounting for critical factors such as temperature, forge press energy, material properties, and even tool temperature to optimize tool design. While mastering this software requires extensive training, its potential to achieve precision and tight tolerances is unparalleled.

With the introduction of the MDR, regulatory requirements for medical device manufacturing continue to grow more stringent. This makes advanced forging technology essential to ensuring repeatability and reproducibility in production.

From my perspective, I welcome the end of the "black magic" era and the industry's shift toward a scientific approach to forging—one that embraces innovation, precision, and regulatory compliance.

Comments